Your manufacturing process shouldn’t be managed and tracked using spreadsheets and manual calculations. Revolutionary Manufacturing Resource Planning ( MRP) systems, like MRPeasy, can transform manufacturing operations and streamline manufacturing processes, from planning and purchasing to inventory management. We’re covering everything you need to know about this software for manufacturers, including how it can simplify your operations and eliminate the hurdles that stand in the way of your success. With its user-friendly interface and robust features, MRPeasy ensures you can stay organized, optimize resources, and boost productivity like never before.

Compare the Best Software for Your Team

Compare Top Software →Understanding the manufacturing process

The manufacturing process is the backbone of any successful business. It encompasses a series of interconnected steps, from raw material procurement to the final product delivery. This intricate process involves various elements such as production planning, inventory management, quality control, and logistics coordination. Manufacturers must navigate these complexities to ensure efficient manufacturing operations, minimize costs, and meet customer demands.

ALSO READ: Manufacturing Resource Planning Systems (MRP): The Future of Efficiency – Exploring the Benefits

At the heart of streamlining manufacturing processes lies the need for effective resource planning and optimization. To do this, manufacturers must clearly understand their production capacity, material requirements, and workflow to make informed decisions and maintain a competitive edge. This is where the importance of a robust Manufacturing Resource Planning (MRP) system comes into play.

Project Management Templates Toolkit

21 proven templates to eliminate guesswork and save hours.

$79 — Download Toolkit →MRP systems provide manufacturers with a comprehensive solution to manage their production processes, from initial planning to final product delivery. By integrating various aspects of the manufacturing cycle, MRP software empowers businesses to streamline manufacturing, reduce waste, and improve overall efficiency. With the right MRP system, manufacturers can gain visibility into their production schedules, optimize inventory levels, and make data-driven decisions to enhance their competitiveness.

The limitations of traditional manufacturing methods

Traditional manufacturing methods often rely on manual processes, spreadsheets, and disparate systems to manage the various aspects of the production cycle. This approach can lead to several challenges that hinder a manufacturing business’s overall efficiency and profitability.

Lack of real-time visibility and data integration

A primary limitation of traditional manufacturing methods is the lack of real-time visibility and data integration. Manufacturers often struggle to obtain a clear, consolidated view of their operations, as information is scattered across multiple platforms and databases. This makes it difficult to make informed decisions, identify bottlenecks, and promptly respond to changing market conditions.

Coordinating various departments and functions

Another common challenge is coordinating various departments and functions within the organization. Without a centralized system, communication and collaboration between teams, such as production, inventory, and procurement, can become fragmented and inefficient. This can lead to delays, errors, and suboptimal resource utilization, ultimately impacting the overall productivity and profitability of the business.

Reliance on manual calculations and data entry

Traditional manufacturing methods often rely on manual calculations and data entry, which can be time-consuming, error-prone, and prone to human bias. This can result in inaccurate forecasting, inefficient purchasing decisions, and suboptimal production planning, hindering the manufacturer’s ability to meet customer demands and maintain a competitive edge.

What is MRPeasy?

This Manufacturing Resource Planning ( MRP) platform offers powerful demand forecasting, order management, and production planning tools. These tools enable informed decisions and reduce lead times. Ultimately, they will streamline manufacturing and make your supply chain more efficient.

How MRPeasy’s MRP software can streamline manufacturing processes

MRPeasy, a leading Manufacturing Resource Planning (MRP) software, offers a comprehensive solution to overcome the limitations of traditional manufacturing methods. By integrating various aspects of the production cycle, MRPeasy empowers manufacturers to streamline manufacturing, optimize resource utilization, and enhance their overall efficiency.

Real-time visibility and data integration

One of the key advantages of MRPeasy’s MRP software is its ability to provide real-time visibility and data integration across the entire manufacturing process. The software seamlessly connects different departments, such as production, inventory, and procurement, allowing for a centralized and consolidated business view. This enables manufacturers to make informed decisions, identify bottlenecks, and respond more effectively to changing market conditions.

Automation of various workflows

MRPeasy’s MRP software also automates various workflows, reducing the reliance on manual processes and minimizing the risk of errors. By automating tasks such as production planning, inventory management, and order fulfillment, the software helps manufacturers save time, improve accuracy, and enhance overall productivity. This, in turn, allows them to focus on strategic initiatives and drive continuous improvement within their operations.

Key features and benefits of MRPeasy’s MRP software

MRPeasy’s MRP software is designed to address manufacturers’ unique challenges, offering a comprehensive suite of features that can revolutionize their operations.

Workflow automation

One of MRPeasy’s standout features is its intuitive and user-friendly interface. The software is designed to be easily navigable, with clear and concise dashboards that provide real-time insights into the manufacturing process. This makes it accessible for users of all skill levels, enabling seamless adoption and integration within the organization.

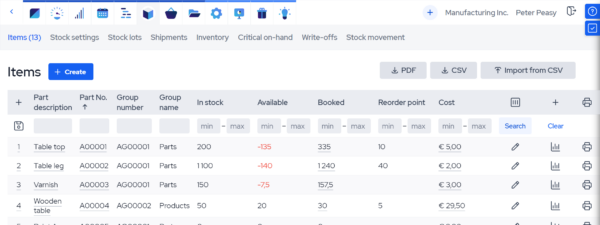

Inventory management

Another key feature of MRPeasy is its robust inventory management capabilities. The software provides manufacturers with a centralized platform to track and manage their inventory levels, ensuring optimal stock levels and minimizing the risk of stockouts or overstocking. This inventory management optimization can lead to significant cost savings and improved cash flow for the business.

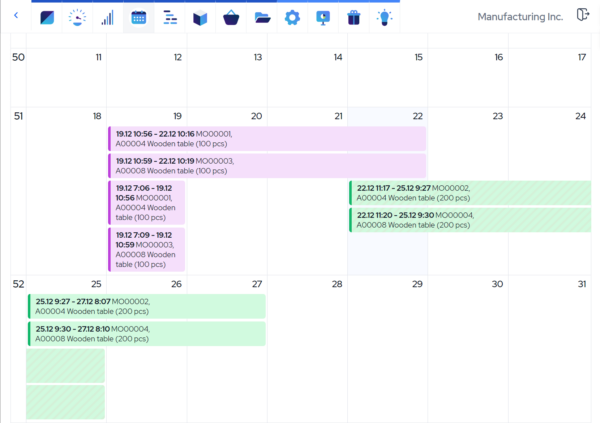

Production planning and scheduling

MRPeasy’s MRP software also excels in production planning and scheduling. The software’s advanced algorithms and forecasting tools enable manufacturers to create accurate and efficient production schedules, considering resource availability, lead times, and customer demands. This helps minimize production delays, reduce waste, and improve delivery times.

Case studies: Real-life examples of businesses that have benefited from MRPeasy

To better understand the transformative impact of MRPeasy’s MRP software, let’s explore some real-life case studies of businesses that have successfully implemented the solution.

Mid-sized electronics manufacturer – inefficient inventory management

One such example is ABC Manufacturing, a mid-sized electronics manufacturer. Before adopting MRPeasy, ABC struggled with inefficient inventory management, resulting in frequent stockouts and lost sales opportunities. By implementing MRPeasy’s MRP software, the company was able to gain real-time visibility into its inventory levels and automate the replenishment process. This led to a 25% reduction in inventory carrying costs and a 15% increase in on-time delivery rates.

Growing furniture manufacturer – managing a complex supply chain and production schedule

Another success story is XYZ Furniture, a growing furniture manufacturer. Faced with managing a complex supply chain and production schedule, XYZ Furniture turned to MRPeasy’s MRP software. The software’s advanced production planning and scheduling features enabled the company to optimize its production process, leading to a 20% increase in production capacity and a 12% reduction in lead times.

These case studies demonstrate the tangible benefits that businesses can achieve by leveraging MRPeasy’s MRP software. By streamlining manufacturing processes, these companies have enhanced their operational efficiency, reduced costs, and improved their overall market competitiveness.

Implementing MRPeasy: Steps to integrate the software into your manufacturing operations

Integrating MRPeasy’s MRP software into your manufacturing operations can be seamless and straightforward. Here are the key steps to ensure a successful implementation:

- Assess your current manufacturing process: Evaluate your existing manufacturing processes, identify pain points, and understand your business’s specific needs. This will help you determine the features and functionalities of MRPeasy that will most benefit your operations.

- Customize the software to your requirements: MRPeasy’s MRP software is highly configurable, allowing you to tailor the platform to your unique manufacturing processes. Work closely with the MRPeasy team to set up the software, configure workflows, and integrate it with your existing systems and data sources.

- Migrate your data: Work with the MRPeasy team to ensure a smooth data migration process by transferring your existing manufacturing data, such as product information, inventory levels, and customer orders, into the new system.

- Train your team: Provide comprehensive training to your employees on how to use MRPeasy’s MRP software effectively. This will ensure your team can leverage the platform’s full capabilities and drive maximum value for your business.

- Monitor and optimize: Continuously monitor the performance of MRPeasy’s MRP software within your manufacturing operations. Identify areas for improvement, make adjustments as needed, and leverage the platform’s reporting and analytics tools to drive ongoing optimization.

Training and support options for using MRPeasy effectively

Ensuring the successful and ongoing utilization of MRPeasy’s MRP software is crucial for maximizing its benefits. To help your team effectively use the platform, MRPeasy offers a range of training and support options.

Comprehensive online documentation and user guides

One resource available is the comprehensive online documentation and user guides. These materials provide step-by-step instructions, tutorials, and best practices for navigating the various features and functionalities of the MRP software. Your team can refer to these resources anytime to enhance their understanding and troubleshoot any issues they may encounter.

Live training sessions and webinars

In addition to the online resources, MRPeasy also offers live training sessions and webinars. The company’s expert team leads these interactive sessions and covers various topics, from basic software usage to advanced optimization techniques. These training opportunities ensure that your employees stay up-to-date with the latest features and can leverage the full potential of the MRP software.

Dedicated customer service team

For ongoing support, MRPeasy provides a dedicated customer service team that is available to assist you with any questions or concerns. Whether you need help with software configuration, troubleshooting, or strategic guidance, the MRPeasy team is committed to ensuring your success and the seamless integration of the MRP software into your manufacturing operations.

Pricing and subscription plans for MRPeasy’s MRP software

MRPeasy Start Free Trial → to cater to the diverse needs of manufacturing businesses of all sizes.

Starter Plan – $49/user/month

The company’s entry-level plan, known as the “Starter” plan, is designed for small-scale manufacturers and startups. This plan provides access to the core features of the MRP software, including production planning, inventory management, and order processing, at a cost-effective monthly subscription.

Professional Plan – $69/user/month

MRPeasy offers the “Professional” plan for medium-sized and growing manufacturing businesses. This plan includes advanced features such as multi-site management, demand forecasting, and custom reporting, providing a more comprehensive solution to meet the evolving needs of your manufacturing operations.

Enterprise Plan – $99/user/month

MRPeasy offers the “Enterprise” plan for large-scale enterprises with complex manufacturing requirements. This plan provides enterprise-level capabilities, including advanced integrations, custom workflows, and dedicated support from the MRPeasy team. The pricing for the Enterprise plan is tailored to your organization’s specific needs, ensuring a solution that aligns with your budget and business objectives.

Regardless of your plan, MRPeasy offers a flexible and scalable pricing model, allowing you to adjust your subscription easily as your manufacturing needs evolve. Additionally, the company provides a free trial period, enabling you to experience the benefits of the MRP software firsthand before committing to a long-term subscription.

Note: Plans can also be purchased at reduced costs based on annual subscriptions.

The future of manufacturing with MRPeasy’s MRP software

As the manufacturing landscape continues to evolve, the need for efficient and adaptable production processes has never been more crucial. MRPeasy’s MRP software stands at the forefront of this transformation, offering manufacturers a comprehensive solution to streamline manufacturing, optimize resource utilization, and enhance their overall competitiveness.

Manufacturers can unlock a world of possibilities by leveraging the power of MRPeasy’s MRP software. From real-time visibility and data integration to automated workflows and advanced production planning, the platform empowers businesses to make informed decisions, reduce costs, and improve customer satisfaction.

The future of manufacturing lies in the seamless integration of technology and data-driven insights. MRPeasy’s MRP software is at the heart of this revolution, providing manufacturers with the tools and capabilities needed to thrive in an increasingly competitive and dynamic market. By embracing this transformative solution, businesses can position themselves for long-term success, stay ahead of the curve, and redefine the standards of manufacturing excellence.

Find out Start Free Trial → can help you streamline your manufacturing processes.

ALSO READ: The Ultimate Guide to Effective Project Management in the Manufacturing Industry

Compare the Best Software for Your Team

Compare Top Software →Project Management Templates Toolkit

21 proven templates to eliminate guesswork and save hours.

$79 — Download Toolkit →